The main goal of the project is to develop an advanced environmentally friendly technology for producing new biodegradable composite materials with improved sound insulating and sound absorbing properties. Composites will reduce noise levels by 8-30 dBA in the specified frequency and temperature ranges. An increase in the insulating and absorbing ability of composites in the sound range will be achieved by using viscoelastic polymer components modified with nanosize carbon and silicate particles as the matrix phase. The application of nanotechnology and the use of special fillers will allow to achieve new properties in acoustic composites - thermal insulation and absorption of electromagnetic radiation of the microwave range. To measure the properties of new material, custom setup will be devised utilizing hardware, software and Machine Learning to optimize the material and constructions characterization process.

The problem of reducing the levels of acoustic impact on the environment or indoor is currently one of the main problems of safe human life and the trouble-free functioning of complex technical objects. Creating less noisy technical devices and equipment could not solve the problem, since at the same time there is a significant increase in the produced units. In some areas, for example, aviation and the air force, the urgency of the problem is steadily increasing, as the intensity and timing of uninterrupted flights and, accordingly, the continuous acoustic loading of aircraft crews and airport staff and maintenance personnel are increasing significantly. The European Union’s Green Book asserts that more than 20% of the world's population is exposed to temporary acoustic impacts, and 170 million European citizens live in areas subject to noise attacks during the daytime. On the other hand, the protection of the acoustic component of the information involves the development of passive methods and means of maximally attenuating the acoustic energy of sound sources. The current thorough analysis of the technical aspects of the noise pollution and insulation problems shows that the construction materials will play a key role in reducing acoustic noise levels.

The aim of the project is to identify the appropriate ingredients and to develop technologies for producing sound-insulating and sound-absorbing composite materials to reduce the energy of wide-range acoustic radiation, including short-term impulsive influences, which make it possible to meet the requirements of noise ecology and acoustic safety of the human environment and nature.

The main tasks of the project are i) development of numerical methods for the structure modelling of noise-reducing composite materials with improved sound-insulating and sound-absorbing properties in a wide frequency range; ii) identifying of the mechanisms and examining the patterns of sound pressure reduction in viscoelastic media containing complex nanoscale fillers; iii) development of methods for material’s structure modification combined with variation of the technological modes to matching the input impedance of the condensed absorber with the wave impedance of the environment, this way minimizing the reflected waves; iv) experimental optimization of the compounding technology, the structure and the dimension of the components according to the criterion of best attenuation of the sound energy; v) development of a new technology for environmentally friendly multifunctional acoustic composite materials.

Enhancement of the insulating and absorption capacity and ability of the developed composites will be achieved by using as a matrix viscoelastic polymer modified with nanosized carbon and silicate particles. In order to guarantee the environmental protection of the production, operation and disposal of the proposed acoustic composites, the technology to be developed within the project envisages the use of natural fibers, which will allow the production of partially biodegradable materials. In addition, it is foreseen to ensure the multifunctionality of the composites by modifying the polymer matrix with fine particles of amorphous metal alloys and ingredients with chirality properties (chiral components), which will give the developed acoustic materials the properties of microwave absorbers and thus be able to be used for objects with low radar visibility.

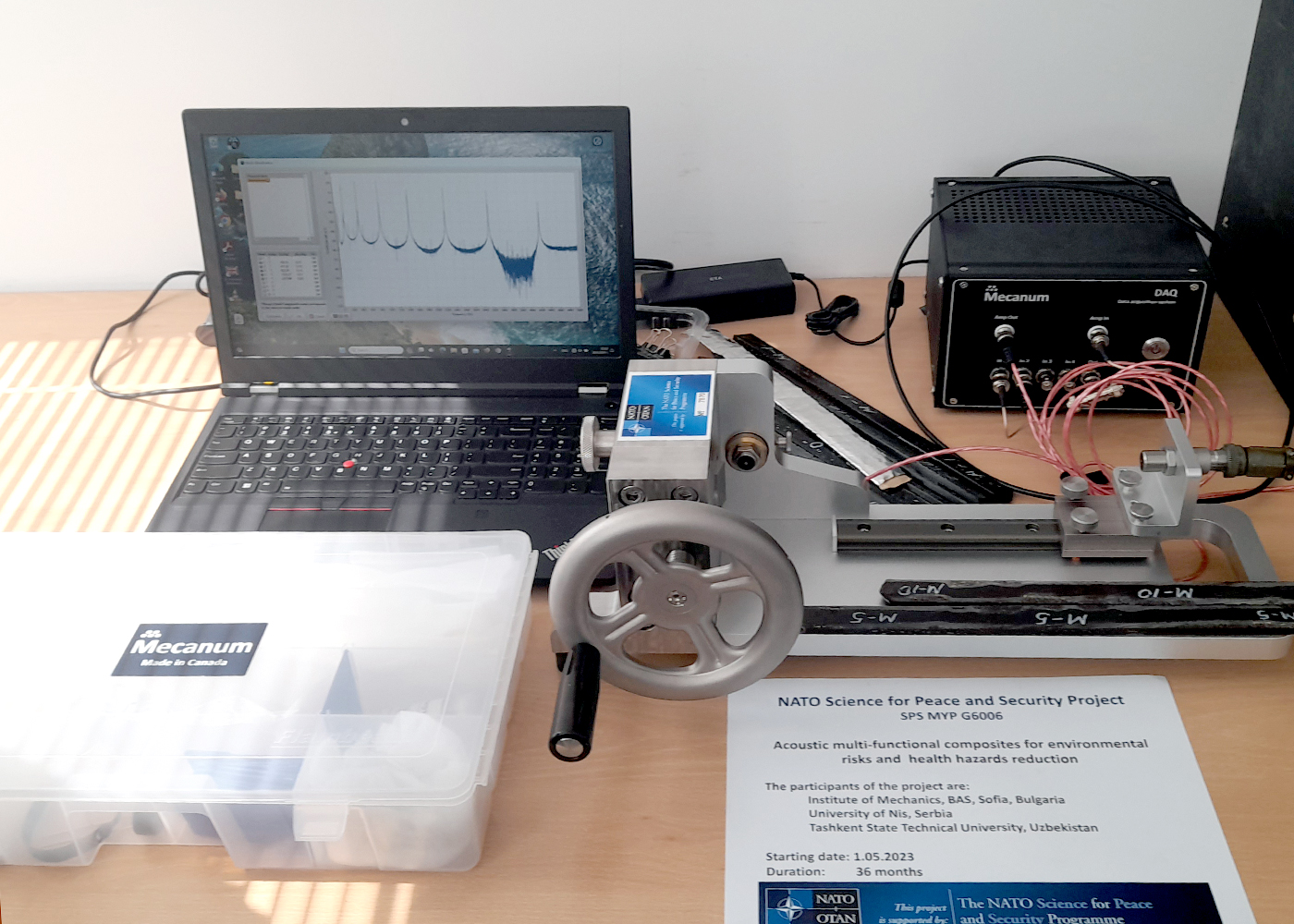

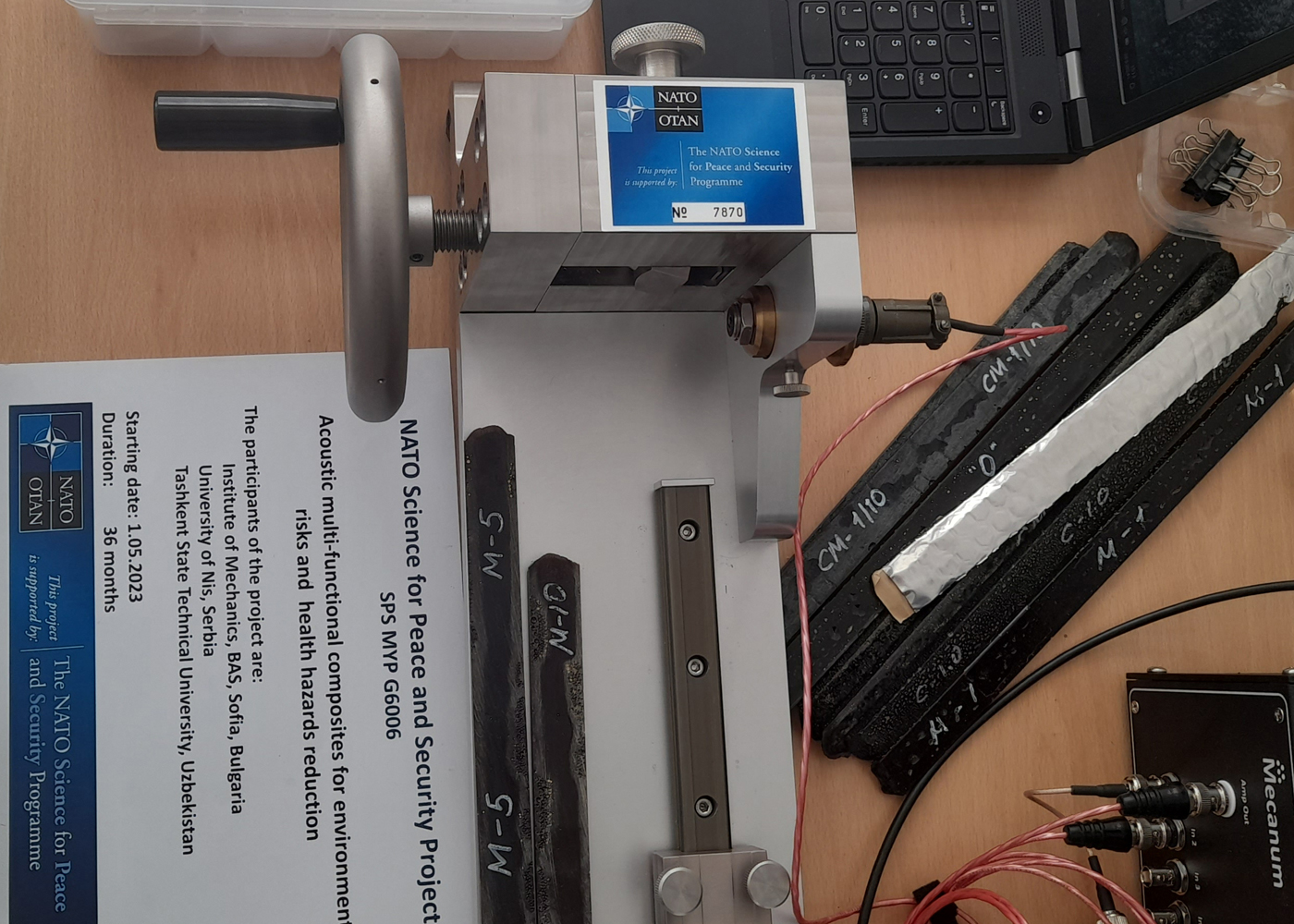

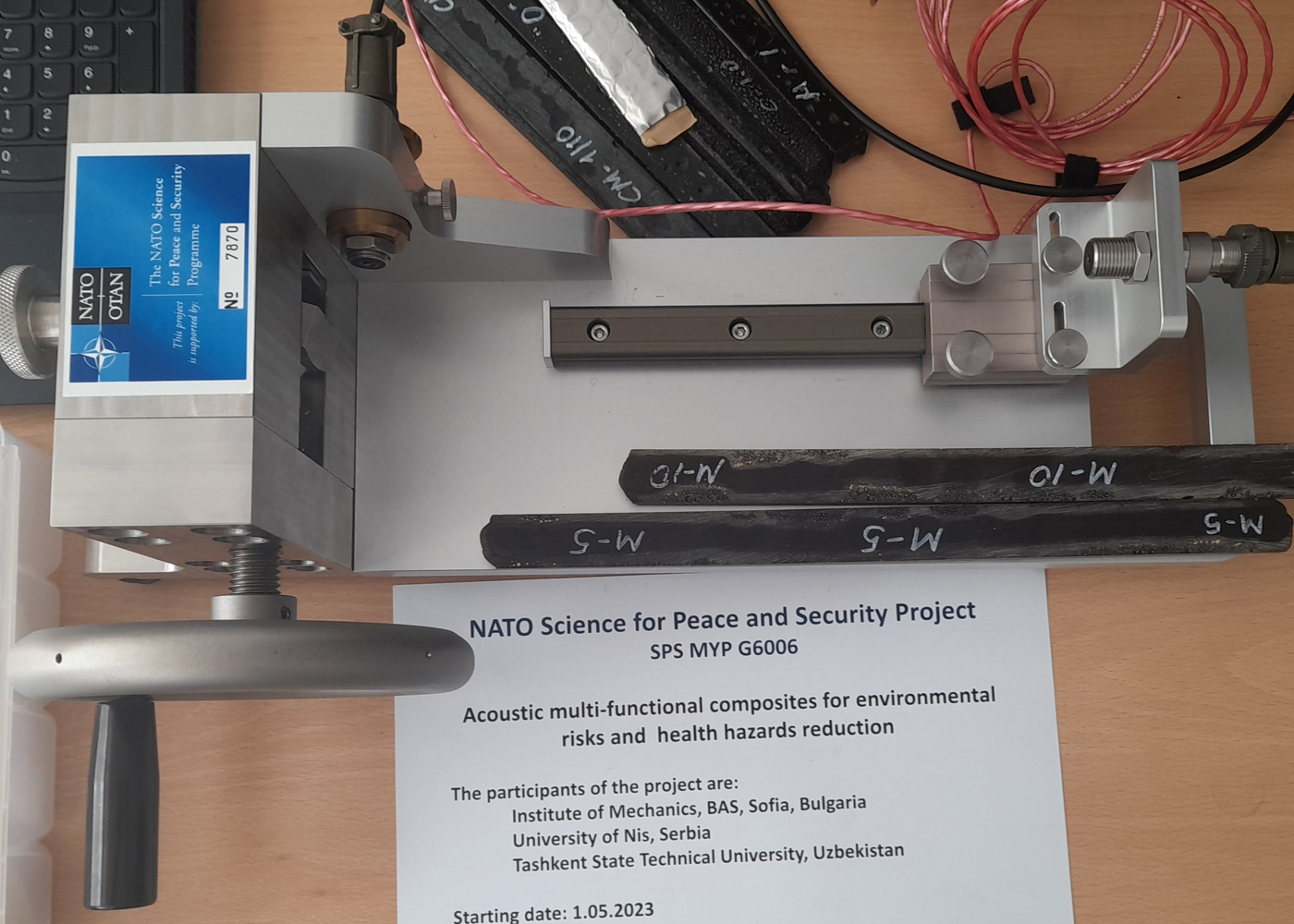

Characterization of the composite material properties will be optimized through utilization of the Machine Learning (ML). Data for the ML optimization will be gathered from the simulation models, laboratory measurements of the material properties, as well as from real-time data logging once material is applied in industrial environment. For the purpose of real-time data gathering, custom measurement setup based on the microphone arrays will be developed, its algorithms optimized using ML methods and appropriate database and web IT server system created. This unique database will be extremely useful for investigation of composite material properties consistency and its mechanical wear and tear, after being applied in harsh environment.

The expected results of the project are i) a new design-experiment technique for determining the properties of sound-absorbing media; ii) a methodology for numerical modelling of the behaviour and the acoustic properties of composite materials and noise-reducing constructions; iii) new composites, allowing to reduce the noise level by 8-30 dBA in the specified sound frequency and temperature ranges, having the properties of biodegradability, thermal insulation and absorption of electromagnetic radiation. Moreover, an experimental verification of the effectiveness of composites will be performed with the assistance of potential consumers (end users). The execution of the project will provide training and raising of the professional skills level of the project members in the field of vibroacoustics

- Institute of Mechanics, Bulgarian Academy of Sciences, Sofia, Bulgaria (IMech BAS)

- Faculty of Occupational Safety in Nis, University of Nis, Niš, Serbia (FOS UNI)

- Tashkent State Technical University, Tashkent, Uzbekistan (FT-TSTU)

- “Resor” doo Gadzin Han, Serbia

- “Piskent Pakhta Tozalash” JSC (Piskent Cotton Gin Plant), Tashkent region, Uzbekistan

- “Kompozit nanotexnologiyasi” Ltd, Tashkent, Uzbekistan

NATO Country Project Director (NPD): PhD Roumen Iankov - IMech BAS

Partner Country Project Director (PPD): PhD Momir Prascevic - FOS UNI

Project Co-Director (PCD): DsC Nodira Abed - FT-TSTU

The participants from FOS UNI:

Momir Prascevic, Darko Mihajlov, Mladena Lukic, Milena Mancic, Nikola Misic

Industrial Partners / End Users:

RESOR d.o.o. (Serbia)

“Piskent Pakhta Tozalash” JSC (Uzbekistan)

“Kompozit nanotexnologiyasi” LTD (Uzbekistan)

NATO science website:

http://www.nato.int/science

Project website:

https://3dlab.iict.bas.bg/g6006

Date of meeting: may 04, 2023;

Place of meeting: Sofia, IMech BAS;

The participants from FOS UNI: Miomir Raos - vice dean of FOS UNI, Darko Mihajlov;

The participants from IMech BAS: Roumen Iankov, Maria Datcheva, Alexander Alexiev.

Date of meeting: may 9-10, 2023;

Place of meeting: Sofia, IMech BAS;

The participants from FOS UNI: Miomir Raos - vice dean of FOS UNI, Darko Mihajlov, Mladena Lukic, Momir Prascevic (online);

The participants from IMech BAS: Roumen Iankov, Maria Datcheva, Alexander Alexiev;

The participants from FT-TSTU: Nodira Abed (online);

The participants from NATO Head Office: Dr. Claudio Palestini and Eleonora Colonna (online)

Date of meeting: september 01, 2023;

Place of meeting: Niš, FOS UNI;

The participants from FOS UNI: Miomir Raos - vice dean of FOS UNI, Momir Prascevic, Darko Mihajlov, Mladena Lukic;

The participants from IMech BAS: Roumen Iankov, Maria Datcheva, Alexander Alexiev.

Date of worhshop: February 6, 2024;

Place of meeting: Bulgarian Academey of Sciences, Institute of mechanics, Sofia;

The participants from FOS UNI: Momir Prascevic, Miomir Raos, Darko Mihajlov, Petar Jovanović

The participants from IMech BAS: Roumen Iankov, Maria Datcheva, Alexander Alexiev

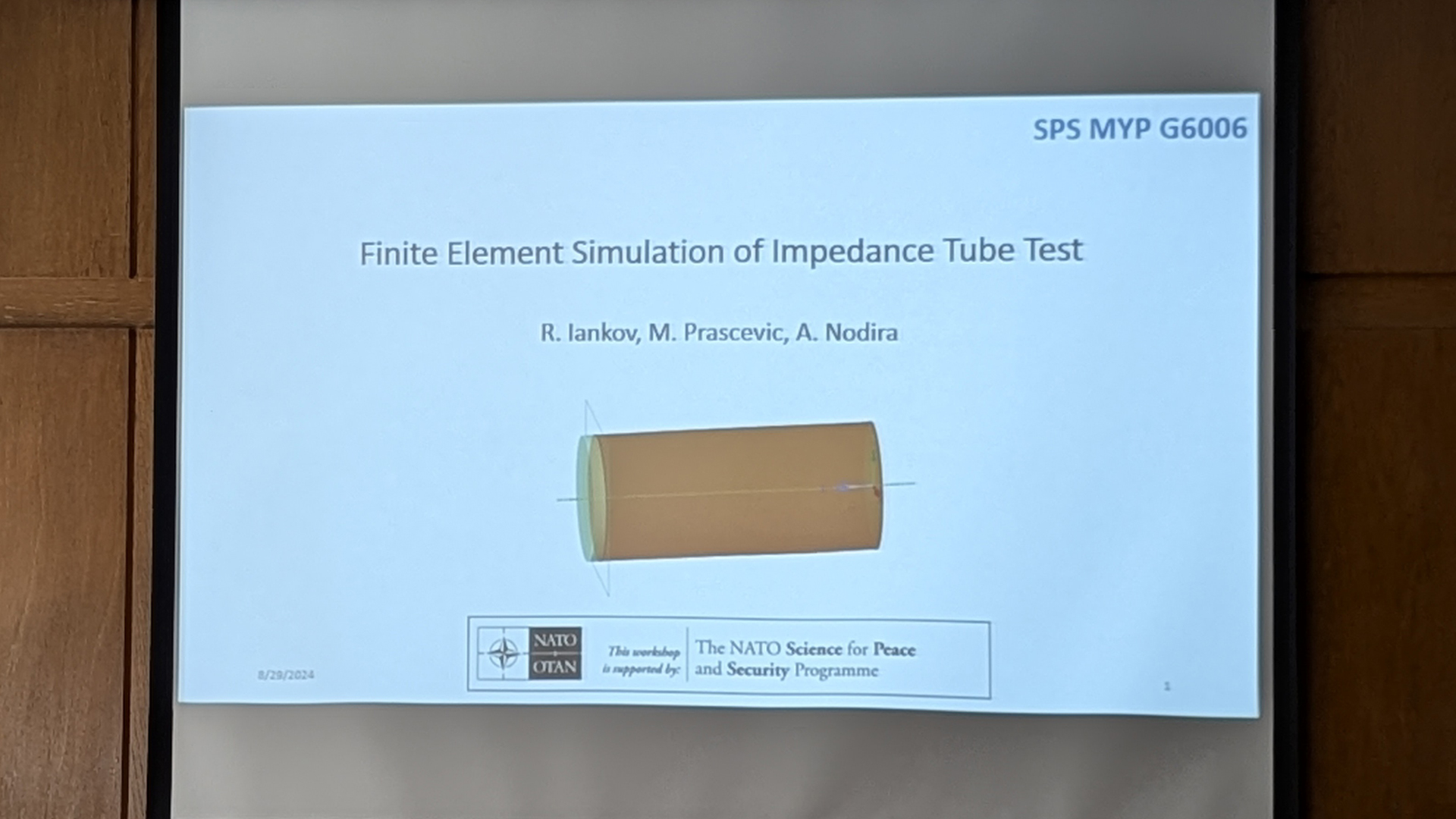

Place: Sozopol, Bulgaria;

Dates of conference: June 10-14, 2024;

Date of round table: June 13, 2024;

The participants from FOS UNI: Momir Prascevic, Darko Mihajlov, Petar Jovanović

The participants from IMech BAS: Roumen Iankov, Maria Datcheva, Alexander Alexiev

The participants from FT-TSTU: Nodira Abed, Bozorov Aminjon

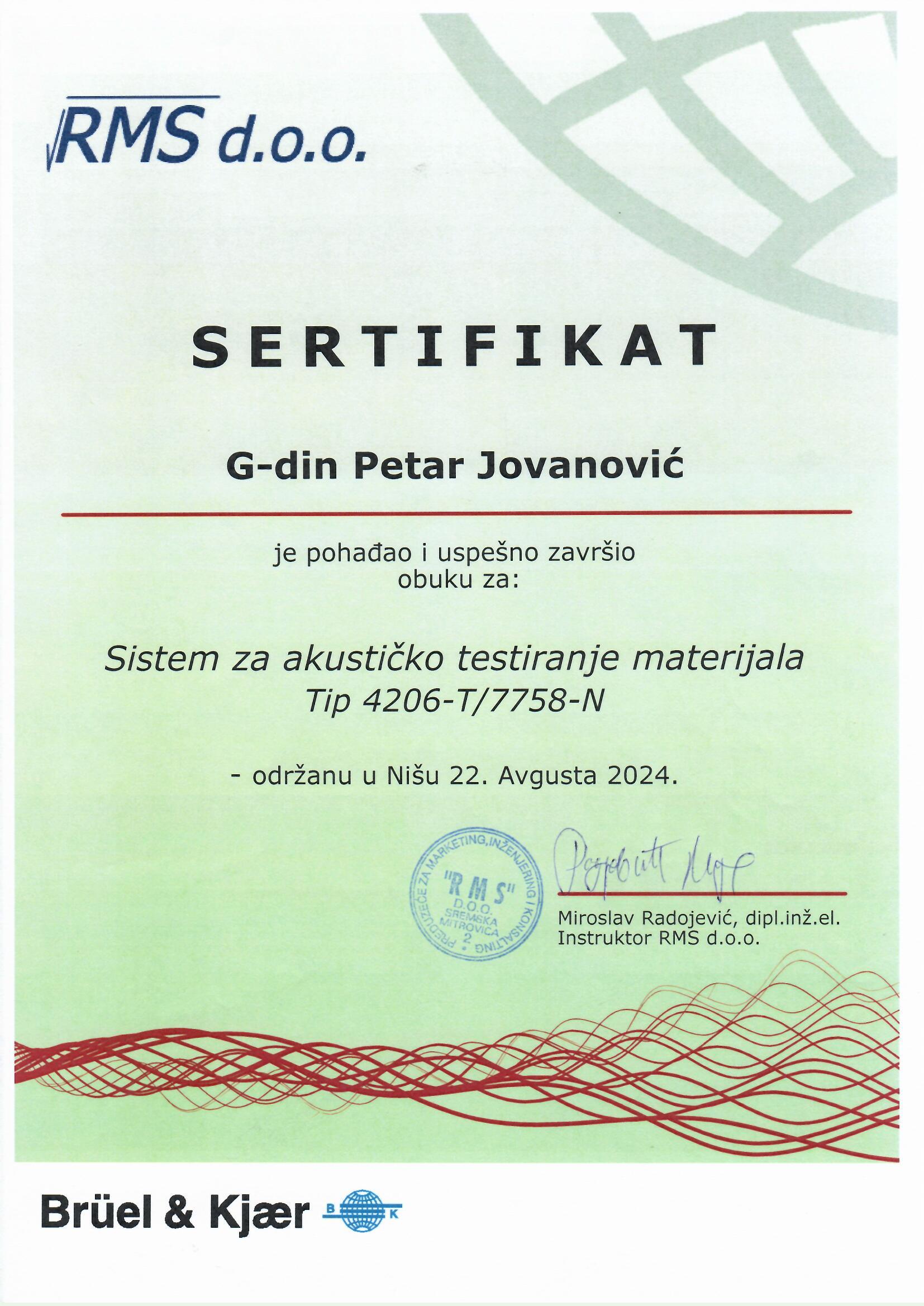

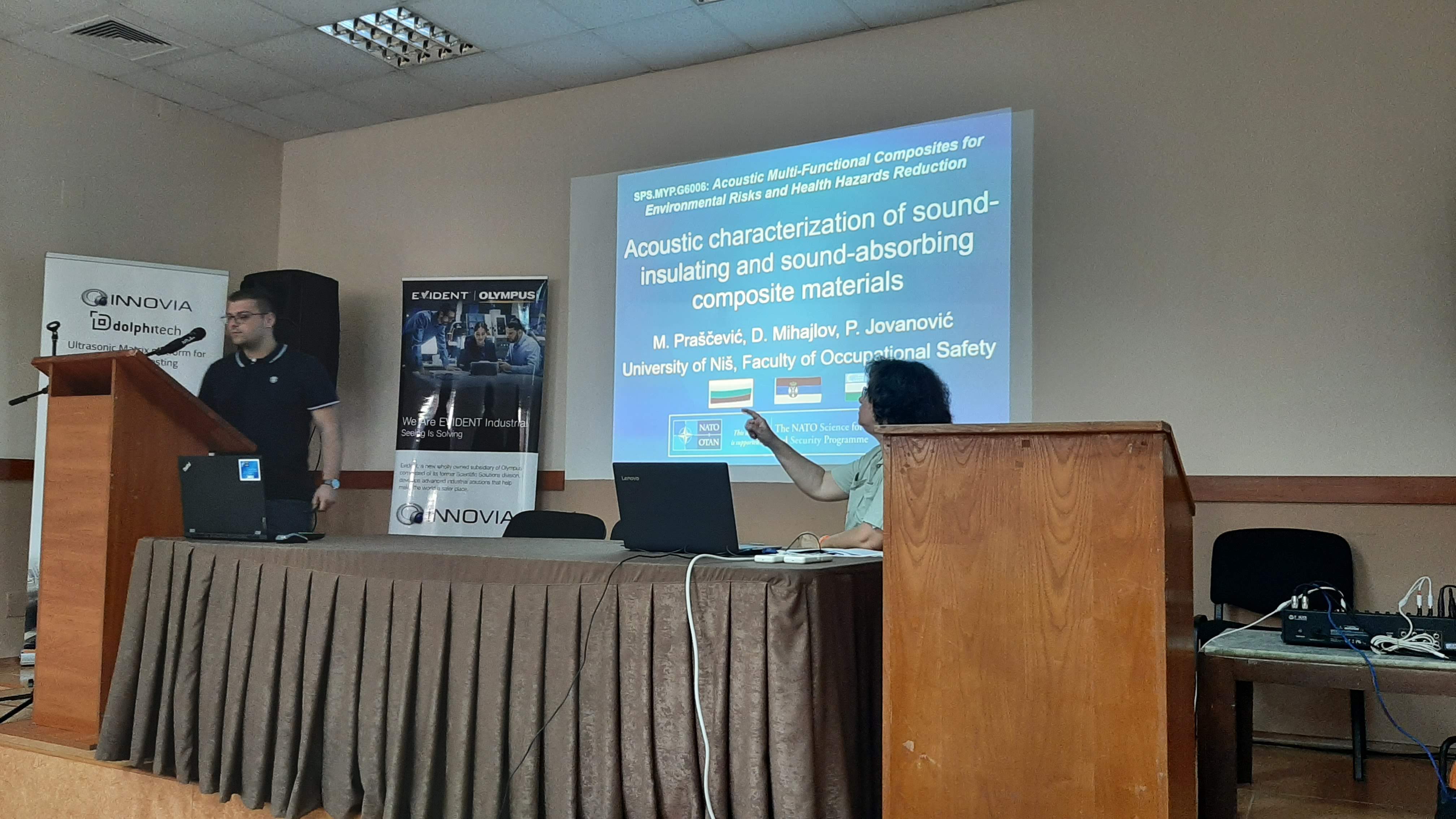

Date of worhshop: August 29, 2024;

Place of meeting: University of Nis, Faculty of Occupational Safety;

The participants from FOS UNI: Momir Prascevic, Miomir Raos, Darko Mihajlov, Mladena Lukić, Milan Protić, Petar Jovanović

The participants from IMech BAS: Roumen Iankov, Maria Datcheva

Date: 24-25 October, 2024;

Place: University of Nis, Faculty of Occupational Safety in Nis, Nis, Serbia

Link:

https://www.znrfak.ni.ac.rs/NOISE2024/index.html

The participants from FOS UNI: Momir Prascevic, Miomir Raos, Darko Mihajlov, Petar Jovanović, Mladena Lukic

The participants from IMech BAS: Roumen Iankov, Maria Datcheva, Alexander Alexiev

Dell OptiPlex 7010 Plus Micro

HP Zbook Power G10

HP ZBook Fury 16 G10

HP Zbook Power G10

INSUL

Sound Insulation Prediction Software

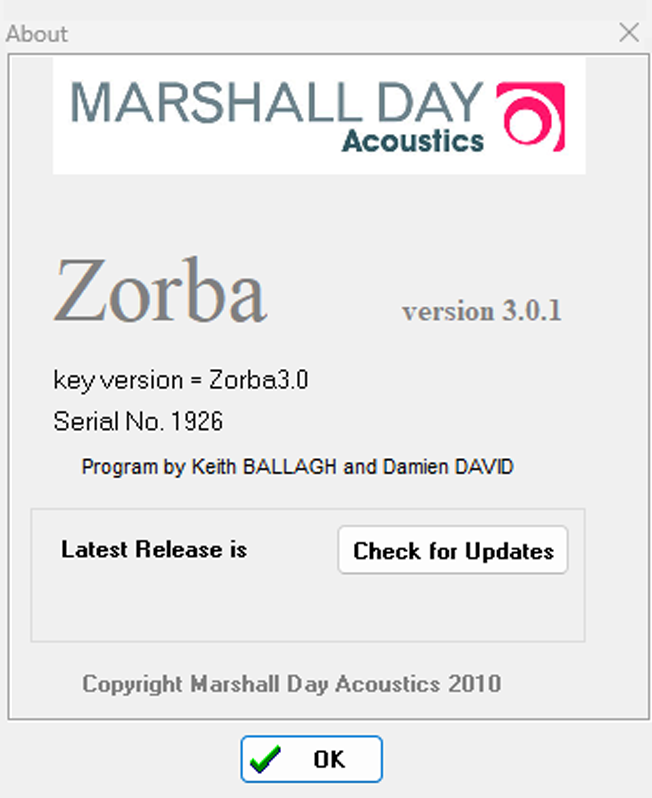

ZORBA

Software for prediction of the sound absorption of building elements

Measurement Partner Suite type 5503 NI with permanent post-processing licence